Description:

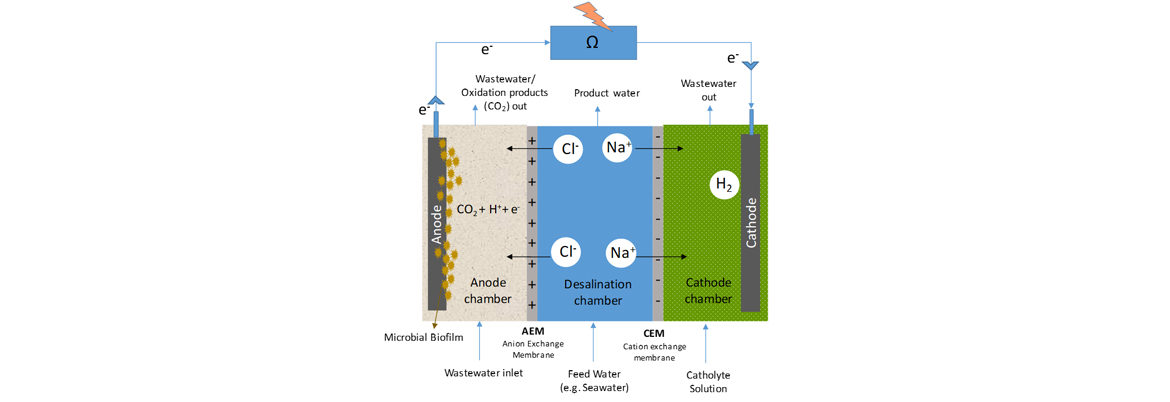

Microbial fuel cells typically consist of two chambers, an anode chamber and a cathode chamber. Unlike the two-chambered MFCs, a typical MDC has a third chamber called the desalination chamber which is created between the anode and cathode chambers with anion and cation exchange membranes positioned at specified distance(s) (see Figure). The desalination capacity of the MDC technology at this developmental stages of the technology has been limited to the de-salting of NaCl solution which has been used to represent seawater.

MDC utilize the exo-electrogenic microorganisms present in the wastewater to breakdown organic matter and transfer produced electrons to the anode to get energy. This causes the accumulation of protons in the anode chamber and so attracting negative ions (Cl–) from the desalination chamber into the anode chamber to balance charge. The transferred electrons at the anode surface travel through an external wire and across an external resistor to reduce oxidized species (electron acceptors) on the cathode causing the movement of cations (Na+) from the desalination chamber into the cathode chamber. By these processes, wastewater is treated, electricity is produced and saltwater is desalinated.

Objective:

One of the MDC technology’s objectives is wastewater treatment, namely the decrease of organic load/ Chemical Oxygen Demand (COD). Nevertheless, MDCs are known to be of significant relevance for simultaneous treatment of wastewater, electricity generation and desalination.

Type of water

Seawater.

Brackish water.

Industrial wastewater.

Municipal wastewater.

Activate sludge.

Applications:

Seawater desalination.

Brackish water desalination.

Wastewater treatment (decrease organic/load and COD, ammonia, nitrate, calcium carbonate, heavy metal removal).

Production of hydrogen and chemicals (acid and alkali production).

Comparison to established technologies:

Advantages:

Multiple applications.

Energy production.

Potential savings in energy consumption when combined with reverse osmosis.

Disadvantages:

Concentration losses

Internal resistance.

Ohmic losses.

Influence of alternate electron acceptors.

Scaling and membrane fouling.

pH imbalance.

The microbial activity is reducing by the high salinity of the feed solution.

Limited potential of exoelectrogens.

Applicability:

TRL 6-7

Technological readiness level (TRL), is an indicator of maturity of a particular technology. TRL is measured on a scale from 1 to 9, 1 being the lowest and 9 being the highest. A TRL of 9 reflects the implementation of an actual system in operational environment.

Reference:

J.C. Mankins, Technology Readiness Levels. White Paper, April, 1995 https://www.spacepropulsion.org/uploads/2/5/3/9/25392309/john_mankins_paper_of_4-6-95_trl.pdf

Other issues:

MDC systems

- Air-cathode MDC

- Biocathode MDC

- Stacked microbial desalination cell

- Recirculation MDC (rMDC)

- Microbial electrolysis – Desalination Integrated System (MEDC)

- Capacitive MDC

- Up-flow MDC

- Osmotic MDC

- Bipolar membrane MDC

- Decoupled MDC

- Separator coupled stacked circulation MDC

- Ion-exchange resin coupled MDC (R-MDC)

- Submerged microbial desalination and denitrification cell (SMDDC)

- Photosynthetic microbial desalination cell/algal-inhibition based microbial desalination cell reactor (PMDC)

- Microbial Reverse Electrodialysis

Hybrid systems:

- MDC-RO

- MDC-ED

Energy production:

MDC produce bioelectricity while desalinating the saline water. It is estimated that about 1.8 kWh of bioelectricity can be generated in MDs by treating 1.0 m3 of wastewater, whereas a RO technology requires 2.2 kWh of electricity for the same amount of water desalination.

References:

.Kokabian, V. G. Gude. Microbial Desalination Systems for Energy and Resource Recovery. Chapter 6.2. Microbial Electrochemical Technology. Sustainable Platform for Fuels, Chemicals and Remediation (2018). Elsevier.

Research directions:

Pilot-scale MDC systems.

Data sources:

- Z. Imoro; M. Mensah; R. Buamah. Developments in the microbial desalination cell technology: A review. Water-Energy Nexus 4 (2021) 76–87.

- K. Srinivas Gujjala; D. Dutta; P. Sharma; D. Kundu; D. N. Vo, S. Kumar. A state-of-the-art review on microbial desalination cells. Chemosphere 288 (2022) 132386.

- Zahid; N. Savla; S. Pandit, V. Kumar Thakur, S. P. Jung, P. Kumar Gupta, R. Prasad, E. Marsili Microbial desalination cell: Desalination through conserving energy. Desalination 521 (2022) 115381.

- Kokabian, V. G. Gude. Microbial Desalination Systems for Energy and Resource Recovery.

- Kokabian, V. G. Gude. Microbial Desalination Systems for Energy and Resource Recovery. Chapter 6.2. Microbial Electrochemical Technology. Sustainable Platform for Fuels, Chemicals and Remediation (2018). Elsevier.

V. Monsalvo; J.M. Ortiz, R. Sadín; B. del Castillo, F. Rogalla; A. esteve-Nuñez. Proyecto europeo MIDES: hacia a desalación sostenible. Retema (2016)