Description:

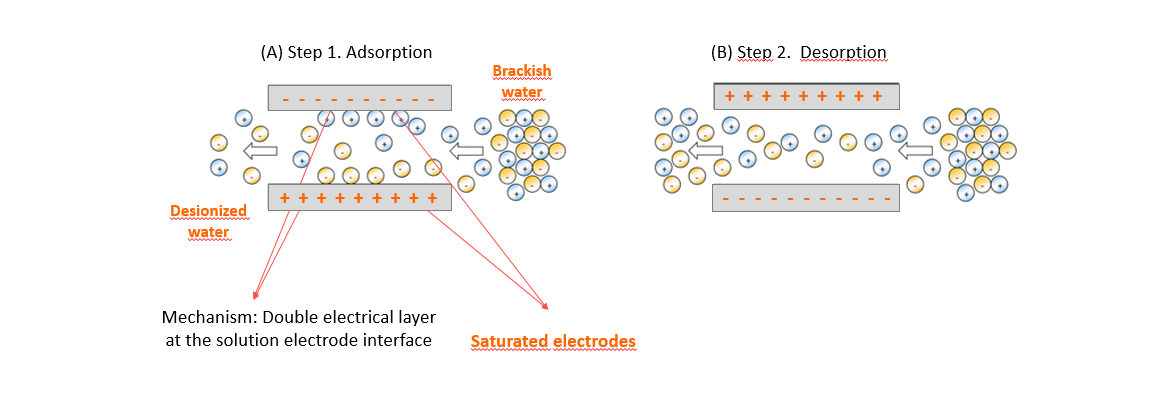

The principle of the capacitive deionization (CDI) process relies on the electrical potential difference over a pair of electrodes remove charged species from the water.

The removal mechanism of CDI can be represented by electrical double layer models in which ions are removed via electrosorption on the electrodes

A conventional technique consolidates two connections enclosed in the circuit facilitating the purpose of current collectors supplying the voltage leading to the electron transfers in a spacer cell between the electrodes. Out of one electrode placed in the cell has been positioned for the splitting of ions: (i) the first electrode facilitates the cation exchange mechanism (ii) While anion exchanging process has been facilitated by the second electrode.

The influent flows through the contiguous cell which comprises electrodes. And the process of ion-exchanges takes place.

The process consists of two steps:

Step 1. Adsorption (Purification): In which the ions get sorbed on the electrode surface till the saturation of electrode occurs i.e. further electrode could no more adsorb the ions over the surface of electrodes

Step 2. Desorption (Regenaration): Here, after adsorption, the electrodes generally get regenerated either be the reversal of the polarity or by shorting the electrodes. Further, the treated water from the process emerges out from the cell via outlet stream. The regeneration step also recovers a portion of the initial charging energy.

Objective:

Instead of removing the bulk water from the salt (as in reverse osmosis, forward osmosis and membrane distillation), capacitive deionization removes the salt from the water.

Type of water:

Brackish water

Seawater under research by FCDI (Flow electrode-CDI) and MCDI (Membrane Capacitive Deionization).

Applications:

Ultrapure water production.

Brackish water desalination.

Water softening.

Selective removal of valuable heavy metals (Arsenic, Lead, Cadmium, Chromium, and Copper).

Selective removal of valuable nutrients: nitrate (NO3–) and phosphate (PO43-).

Bromide removal during seawater desalination.

Waste water treatment.

Seawater desalination under research by FCDI (Flow electrode-CDI) and MCDI (Membrane capacitive Deionization).

Brine concentration (brine from brackish water desalination).

Comparison to established technologies:

Advantages:

Absence of applied pressure.

Low energy requirements and cost-efficient brackish water desalination

Lower fouling potential due to lack applied pressure.

Multiple applications.

Higher rejection of solutes than reverse osmosis.

Adjustable deionization in relation to the rejection of salts (up to 95%)

High water recovery: up to 95%.

No chemicals products are required for water pretreatment

Minimal maintenance compared reverse osmosis.

Temperature range between 5 – 60ºC (Advantage for industrial process water treatment)

The MDCI supports 1 ppm of chlorine continuously and up to 20 ppm in chemical cleanings

Potential savings in energy consumption when combined with RO.

Silica does not affect the system, which does penalize conversion in RO systems.

Disadvantages:

Limited data available for seawater desalination. CDI not applicable for high salinity desalination (seawater).

Electrode efficiency (adsorption performance and energy efficiency).

Process economy (manufacture low-cost and easily scalable electrodes).

It is not effective in removing organic species (no load) and biological species.

Organic fouling (municipal wastewater treatment).

The operation mode of the CDI and the MDCI by cycles seems a limitation with regard to their commercialization.

Applicability:

TRL 6-7 in 2021

Technological readiness level (TRL), is an indicator of maturity of a particular technology. TRL is measured on a scale from 1 to 9, 1 being the lowest and 9 being the highest. A TRL of 9 reflects the implementation of an actual system in operational environment.

J.C. Mankins, Technology Readiness Levels. White Paper, April, 1995 https://www.spacepropulsion.org/uploads/2/5/3/9/25392309/john_mankins_paper_of_4-6-95_trl.pdf

Other issues:

- CDI systems:

Conventional CDI

Membrane-CDI (MCDI)

Flow electrode-CDI (FCDI)

- Hybrid systems:

Reverse Osmosis (RO) – CDI pass system (CDI to treat RO permeate) for ultrapure water production

Reverse Osmosis (RO) – CDI stage system (CDI to treat RO brine) for maximizing water recovery rate in (waste) water treatment.

CDI- Reverse Electrodialysis (RED)

CDI – Microbial Fuel Cell (MFC)