Description:

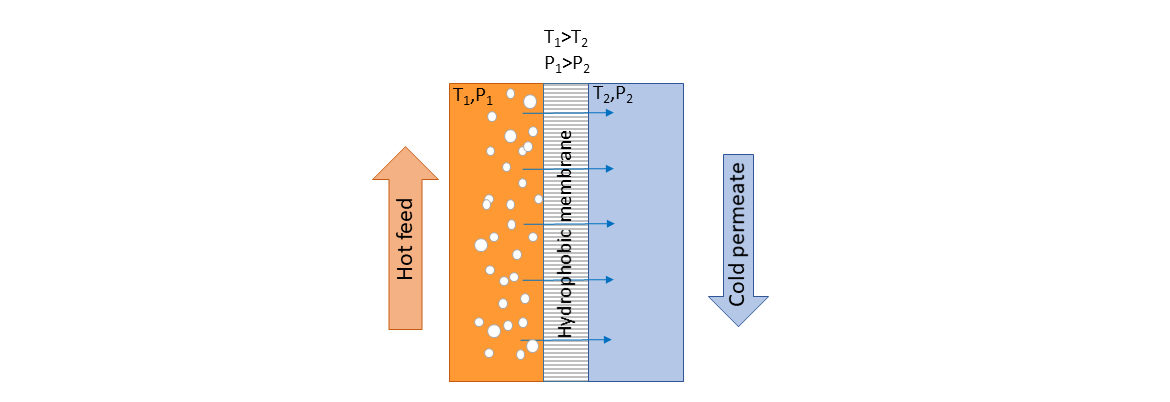

Membrane distillation (MD) is a thermally driven, membrane-based process that combines membrane technology and evaporation processing in one unit. It involves the transport of water vapor through the pores of hydrophobic membranes via the temperature difference across the membrane. This difference results in a vapor pressure differential, leading to the transfer of the produced vapor through the hydrophobic membrane to the condensation surface. So, instead of a pressure or concentration difference, the driving force for the MD processes is the vapor pressure difference across the membrane. In MD, performance is not affected by the salinity of the feed water. However, the permeate flux is strongly affected by the feed temperature.

Objective:

Fresh water production.

Concentration solutions.

Type of Water:

Seawater.

High salinity brine.

Wastewater.

Applications:

Seawater desalination.

Brine/ Hypersaline desalination.

Waste water treatment (for example: ammonia recovery form wastewater)

Zero Liquid Discharge (ZLD).

Comparison to Established Technologies:

Advantages:

Absence of applied pressure.

High rejection capacity with the removal of non-volatiles.

No limitations on feed water total dissolved solids.

Lower operating temperatures when used in vacuum.

Possibility of utilizing plastic material to avoid corrosion.

Minimal effect of performance due to feed salt concentrations.

Possibility of utilizing different energy sources, such as waste heat, solar energy and geothermal.

Disadvantages:

Lack of membranes and modules designed.

Thermal polarization.

Fouling of hydrophobic membranes is an issue when the membrane is wetted.

Requires pretreatment of feed water source.

Applicability:

TRL 4 – 5 in 2016

TRL 7 in 2020

TRL 9 in 2035

Technological readiness level (TRL), is an indicator of maturity of a particular technology. TRL is measured on a scale from 1 to 9, 1 being the lowest and 9 being the highest. A TRL of 9 reflects the implementation of an actual system in operational environment.

J.C. Mankins, Technology Readiness Levels. White Paper, April, 1995 https://www.spacepropulsion.org/uploads/2/5/3/9/25392309/john_mankins_paper_of_4-6-95_trl.pdf

Plant capacity: 2 – 400 m3/day.

Other Issues:

– Membrane configuration:

Flat sheet.

Spiral wound.

Hollow fiber.

– Configurations:

Direct contact distillation (DCMD).

Air gap membrane distillation (AGMD)

Vacuum membrane distillation (VMD)

Sweeping gas membrane distillation (SGMD)

Energy consumption:

Specific energy consumption, as reported in literature varies for different configurations, feed water concentrations, water recovery, salt rejection etc.

Research directions:

Special wettability membranes.

Integrated heat recovery.

Renewable energy MD.

Hybrid MD systems.

Alternative heating techniques.

Data sources:

– F. E. Ahmed, A. Khalil, N. Hilal. Emerging desalination technologies: Current status, challenges and future trends. Desalination 517 (2021) 115183.

– C. Skuse, A. Gallego-Schmid, A. Azapagicm P. Gorgojo. Can emerging membrane-based desalination technologies replace reverse osmosis? Desalination 500 (2021) 114844.

– M. K. Alsebaeai, A. L.Ahmad. Membrane distillation: Progress in the improvement of dedicated membranes for enhanced hydrophobicity and desalination performance. Journal of Industrial and Engineering Chemistry 86 (2020) 13–34.

– F.E. Ahmed, B. S. Lalia, R.Hashaikeh, N. Hilal. Alternative heating techniques in membrane distillation: A review. Desalination 496 (2020) 114713.

– A. Subramani, J.G. Jacangelo. Emerging desalination technologies for water treatment: A critical review. Water Research 75 (2015) 164-187.