Forward osmosis (FO) is a water separation process in which a semipermeable membrane is used to separate water from dissolved solutes. FO uses natural energy in the form of osmotic pressure to transport water through the membrane while retaining the dissolved solutes on the other side.

Description:

Forward osmosis (FO) is a water separation process in which a semipermeable membrane is used to separate water from dissolved solutes. FO uses natural energy in the form of osmotic pressure to transport water through the membrane while retaining the dissolved solutes on the other side.

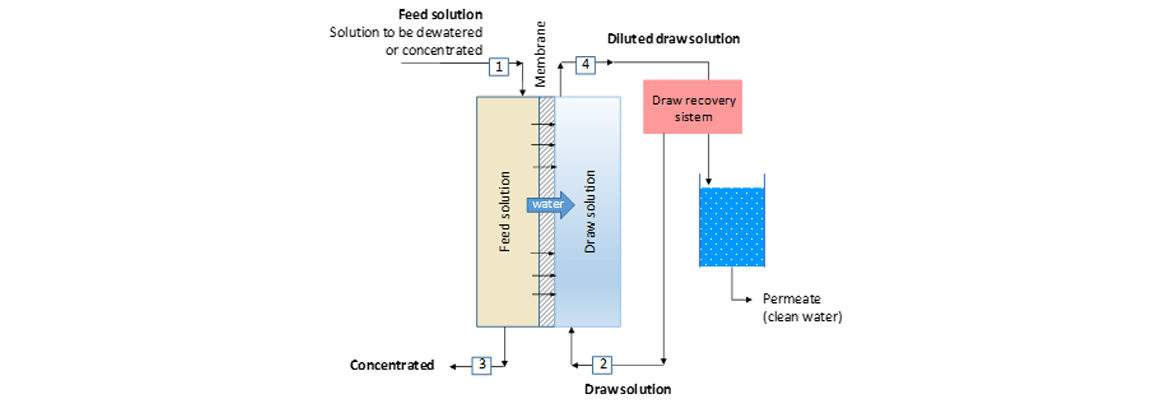

In FO systems, a solution of lower solute concentration (known as the feed solution) flows on one side of the membrane, while a solution of higher solute concentration (the draw solution) flows on the other side. Natural osmosis induces water to flow from the feed solution through the membrane and into the draw solution. As the water moves through the membrane, the draw solution becomes diluted and the feed solution is concentrated.

Objective:

– Product concentration: Water is extracted from the feed solution, leaving a valuable concentrate.

– Waste concentration: Water is extracted from the feed solution, leaving a concentrated waste product that is easy to dispose of.

– Production of clean water: In both valuable product concentration and waste concentration, water moves from the feed solution into the draw solution. This water can then be recovered to produce clean water.

Type of water:

Seawater.

Brackish water.

High salinity brine.

Industrial wastewater.

Municipal wastewater.

Applications:

Seawater desalination.

Brackish water desalination.

Wastewater treatment (concentrated wastewater or diluted wastewater, organics removal, recovery nutrients).

Removal organic matters.

Industrial effluents treatment.

Pretreatment process for reverse osmosis.

Pharmaceutical concentration.

Osmotic hydration bags.

Juice concentration.

Fertigation in agriculture.

Protein enrichment.

Landfill leachate treatment.

Zero Liquid Discharge.

Comparison to Established Technologies:

Advantages:

Multiple applications.

Applicable for high salinity desalination.

Potential savings in energy consumption when combined with RO.

Can utilize waste heat source for generation of draw solution.

High feed water recovery.

Lower fouling potential due to lack of applied pressure. Potential for lesser pretreatment.

Disadvantages:

Limited full-scale installations.

Difficult to choose optimal osmotic agent (draw solution).

Lower flux rates than RO leading to higher membrane area requirement.

Requires specific membranes for FO applications.

Applicability:

TRL 4 – 5 in 2016

TRL 7 in 2020

TRL 9 in 2035

Plant capacity: 10-10000 m3/day.

Technological readiness level (TRL), is an indicator of maturity of a particular technology. TRL is measured on a scale from 1 to 9, 1 being the lowest and 9 being the highest. A TRL of 9 reflects the implementation of an actual system in operational environment.

Reference:

J.C. Mankins, Technology Readiness Levels. White Paper, April, 1995 https://www.spacepropulsion.org/uploads/2/5/3/9/25392309/john_mankins_paper_of_4-6-95_trl.pdf

Other issues:

Draw Solution Characteristics:

non-toxic, stable, near neutral pH, highly soluble to avoid precipitation, can be recovered from the diluted draw solution at low cost using existing technology.

- Gas and volatile compounds: NH4HCO3, Tri-methylamine.

- Inorganic solutes: NaCl, MgCl2

- Inorganic solutes (fertilizers): Ca(NO3)2, KH2PO4, (NH4)2HPO4, K2SO4, NH4Cl, NaNO3, KNO3, (NH4)2SO4, NH4NO3, NH4H2PO4

- Simple organics: Sucrose, glucose, fructose.

- Amphiphilic organic ionic liquids.

- Switchable polarity solvents.

- Organic ionic salts: EDTA.

- Polyelectrolyte draw solutes.

- pH responsive polymers.

- Thermo-responsive copolymer.

- Hydro-acid complexes.

- Stimuli-responsive hydrogels.

- Magnetic nanoparticles functionalized with simple polymers.

- Quantum dots.

- Stimuli responsive nanoparticles.

Membranes configuration:

Flat sheet.

Spiral-wound.

Hollow fiber.

Hybrid systems:

FO-Nanofiltration.

FO-Reverse Osmosis.

FO-Membrane Distillation.

FO-Electrodialyisis.

Energy consumption:

Specific energy consumption, as reported in literature varies for different configurations, feed water concentrations, water recovery, salt rejection etc.

Seawater desalination:

A specific energy consumption of less than 0.25 kWh/m3 for the membrane portion of FO was reported by T.Y. Cath et al. (2009). However, after consideration of the energy consumption associated with draw solution recovery, the specific energy consumption can be energy intensive from 3-68 kWh/m3 C. Skuse et al (2021).

References:

T.Y. Cath, J.E. Drewes, C.D. Lundin, C.D. A novel hybrid forward osmosis process for drinking water augmentation using impaired water and saline water resources. Water Research Foundation and Arsenic Water Technology Partnership.

C. Skuse, A. Gallego-Schmid, A. Azapagicm P. Gorgojo. Can emerging membrane-based desalination technologies replace reverse osmosis? Desalination 500 (2021) 114844.

Research directions:

Draw solutions.

Membrane fabrication and modification.

Fouling phenomenon.

Hybrid FO system.

Data sources:

[2] Skuse, A. Gallego-Schmid, A. Azapagicm P. Gorgojo. Can emerging membrane-based desalination technologies replace reverse osmosis? Desalination 500 (2021) 114844.