The project goal is to design, build and test a SWRO rack that guarantee a SEC below 2.00 kWh/m3 at an industrial scale of 2,500 m3/d and, with the results obtained, scaling it up to 5,000 m3/d.

The desalination pilot plant is installed in DESAL+ Living Lab testing facilities of ITC in Pozo Izquierdo, Gran Canaria Island, Spain.

This new award in honour of Miriam Balaban and with 49 candidates was awarded for the first time during the event Desalination for the Environment, Clean Water and Energy Congress, Limassol – Cyprus, which took place from 22-26 May 2023.

The award honors innovative solutions in the field of desalination, sustainable energy and circular economy processes. A panel of leading experts in Academia and the Desalination Industry selected the finalists and awardee.

The preliminary design adopted average minimum (19.2˚C) and maximum (23.6˚C) feed water temperature conditions throughout the year for the RO rack design. A total of 151 membrane simulations were carried out using two commercial brands. They were simulated using different pumping equipment and ERDs available on the market. The incidence of the following variables in the calculation of SEC, as well as in the mechanical and electrical design, was analyzed qualitatively/quantitatively.

The main objectives related to the final design of the experimental desalination plant at a scale of 2,500 m3/day are:

– Validate a SEC close to 1.85 kWh/m3 (SW 36.8 g/L; Recovery 40%; 19-23˚C; [B] = 4.9 mg/L) including HPP, booster pump, pressure losses from pre-treatment to plant outlet and operation control.

– Validate and measure the actual performance of the installed equipment and compare it with the simulations carried out.

– Use this pilot plant to validate other ITC designs and configurations.

– Extrapolate the results to a technical solution at a production scale of 5,000 m3/d or higher.

The main aspects to highlight for this final design are:

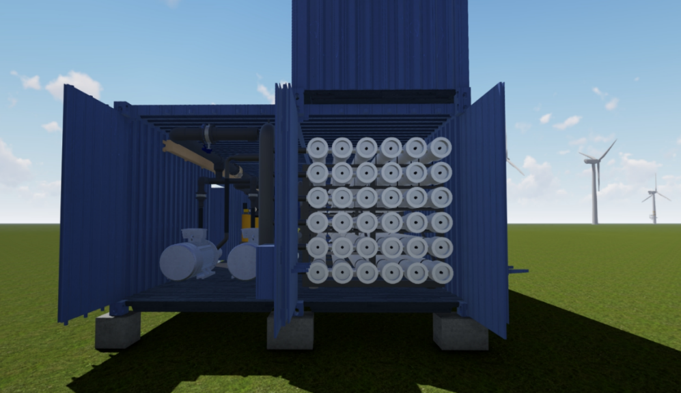

- Compact, mobile and easy to install solution (Plug&Play).

- Containerized solution consisting of 4 maritime containers.

- RO rack with 36 pressure vessels (membranes hybridization: 5 Super Rejection + 2 High Rejection and Low energy consumption).

- 2 positive displacement HPPs (98% yield); 2 pressure exchangers + booster pump; all motors are driven by a VFD (97% performance).

- The pressure losses at high and low pressure are less than 16 bar.

- Compact post-treatment system (calcite + CO2).

DESALRO 2.0 project is funded by REACT-EU, within the framework of the European Recovery Instrument “Next generation” (Exp. SD-2111).